Recently, with the continuous improvement of the construction industry’s requirements for material performance and aesthetics, color-coated plates have been increasingly widely used in the construction field due to their unique advantages, and their market prospects have attracted much attention.

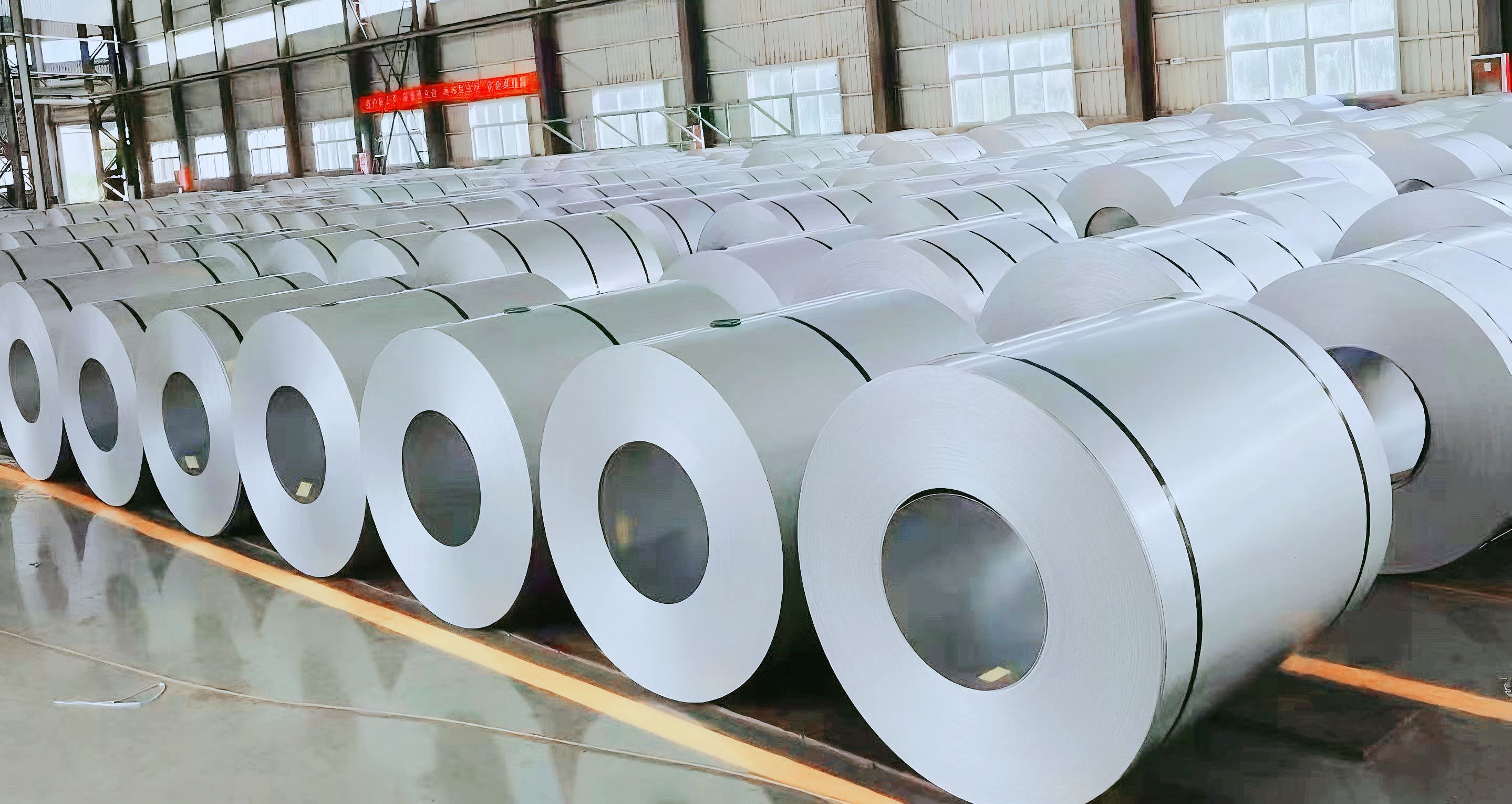

Color-coated plates are products made on a continuous unit with cold-rolled strip steel and galvanized strip steel (electrogalvanized and hot-dip galvanized) as substrates, surface pretreatment (degreasing, cleaning, chemical conversion treatment), continuous coating (roller coating), baking and cooling. Because of its rich colors, strong corrosion resistance, good processing performance, and convenient installation, it has become an ideal building material for the construction industry.

In the construction industry, the application scenarios of color-coated plates are very diverse. In the construction of industrial plants, color-coated plates are often used for roof and wall maintenance structures, which can effectively resist external environmental erosion and extend the service life of buildings. At the same time, their diverse colors can make the appearance of the plant more beautiful. In commercial buildings, such as shopping malls, exhibition halls, etc., color-coated plates can be used for exterior wall decoration. Through the combination of different colors and textures, a unique architectural style can be created to enhance the recognition and attractiveness of the building. In addition, in some temporary buildings and light steel houses, color-coated boards have also been widely used due to their light weight and fast installation.

From the perspective of market prospects, with the continuous advancement of my country’s urbanization process, the demand for building materials in infrastructure construction, commercial real estate development, and residential construction will maintain a steady growth. As a building material with excellent performance and high cost performance, the market demand for color-coated boards is expected to expand further. At the same time, with the continuous improvement of environmental awareness, green buildings have become the trend of future building development. Color-coated board manufacturers are also constantly increasing their R&D investment and launching environmentally friendly color-coated board products to meet the market demand for green building materials.

However, the color-coated board industry also faces some challenges. On the one hand, the market competition is fierce and the product quality is uneven. In order to reduce costs, some companies may sacrifice product quality and affect the reputation of the entire industry. On the other hand, the price of raw materials fluctuates greatly, which brings certain pressure on the cost control of color-coated board manufacturers.

Industry experts said that color-coated board companies should strengthen technological innovation, improve product quality and performance, and continuously launch new products that meet market demand. At the same time, it is necessary to strengthen brand building, improve brand awareness and reputation, and enhance market competitiveness. With the continuous development of the construction industry and the continuous upgrading of market demand, the application prospects of color-coated plates in the construction industry are still broad, and it is expected to make greater contributions to the development of the construction industry.

Post time: Mar-01-2025